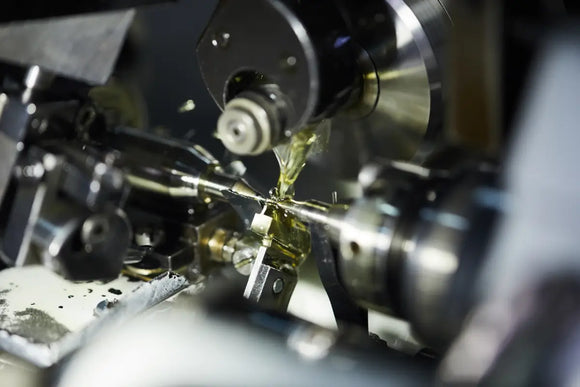

In the world of metal working, precision and performance depend on the quality of your fluids. Next Generation Services delivers expert oil filtration, analysis, and reclamation tailored to the demands of machining, stamping, forming, and cutting operations—so your tools and equipment stay reliable and productive.

Keep your fluids and tooling in top form

Metalworking environments generate heat, friction, and fine particulates—all of which degrade lubricants quickly.

Our services are engineered to:

- Remove water and particulate contamination

- Restore oil quality through filtration, dehydration, and readditization

- Identify wear trends through oil analysis

- Extend fluid life and improve performance

- Minimize unscheduled downtime

Whether you’re working with drawing oils, stamping fluids, or coolants, we help you get the most out of every drop.

Why Choose Next Generation Services?

Precision Fluid Filtration

Maintain tight tolerances and surface finishes by keeping oil and coolants ultra-clean.

Equipment Longevity

Reduce tool wear and machine maintenance with clean, stable fluids.

Fewer Fluid Changeouts

Extend lubricant life and reduce fluid waste through onsite reclamation.

Real-Time Analysis

Get fast lab-backed insights to monitor performance and anticipate issues.

Mobile Service Available

Our Mobile Reclamation Units (MRUs) are ready for emergency and routine service.